ABMF-TH Twin Head

Big filter area for higher grade of contamination.

Big filter area for higher grade of contamination.

Up to 3.200 cm² (2 x 1.600) / 496 sqin (2 x 248) available.

Continuous process.

- Combination of 2 ABMF filter units with manifold block.

- Omission of buffer cylinder.

- Low pressure deviation at change between ABMF cavities.

Compact design.

- Both ABMF units almost vertical mounted.

- Short melt channels.

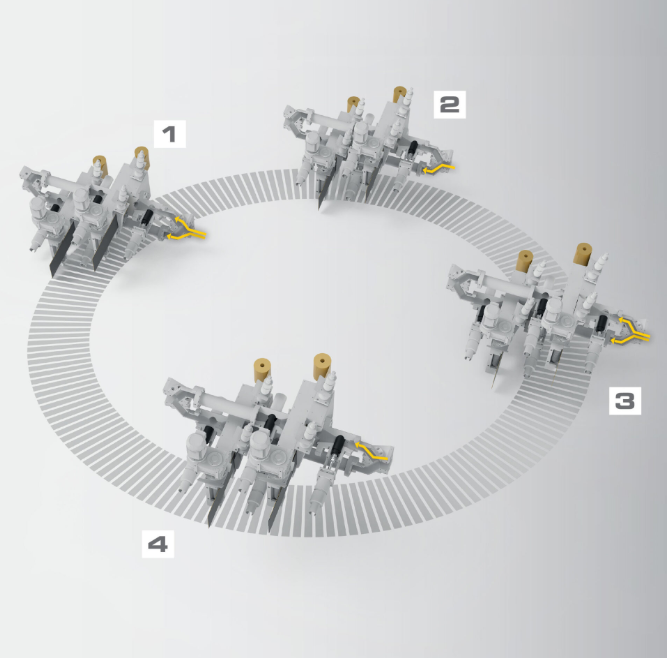

- Continuous melt flow through both filter heads. Initiation of fully automatic screen change when the adjustable limit pressure has been reached in filter head 1 in front of the screen. Valves 1.1 and 1.2 close and the space in front of the screen is depressurized. Wedges open in parallel and re-lease screen belt fixation. Melt flows continuously through filter head 2.

- The screen is guided by driven transport rollers until clean screen is in the filter zone again.

- Wedges close and screen is fixed and sealed again. Valves 1.1 and 1.2 open and melt flows into filter head 1 again.

- Process 1-3 is repeated at filter head 2. After that, the screen change process is completed.