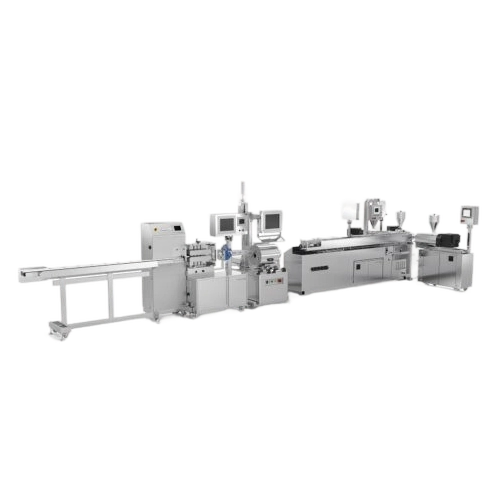

In case of COLLIN strand lines, it is unique that all production steps are provided by a single source – compounding, coextrusion, take-off and cut.

The vertical water bath is the highlight – a COLLIN innovation, which guarantees reliable roundness.

For an exact throughput of the line, the extruders are equipped with melt pumps and pressure/speed controls. By using a multi-layer die, the strand is directly and vertically extruded into a water bath. This process eliminates any influence of a calibration system. The gravitation guarantees high accuracy of diameter and roundness.

Moreover, a continuous water flow guarantees an absolutely calm water surface when the product enters the cooling tank.

Advantages

- All production steps from one source

- Reliable roundness and diameter by vertical water bath

- Different take-off speeds

- Manufactured according to FDA 21 CFR, ISPE, ISO 13485, Din EN 10204/3.1B, cGMP/GMP

- The design meets the hygienic standards

- Easy cleaning

- Enormous variability in production

- Continuous production, compliance with all tolerance specifications

- Lines which can produce around the clock

- Medically approved stainless steel for all parts having contact with the product

- All surfaces with a very low degree of roughness for easy cleaning and disinfection

- Standards-compliant validation, qualification and documentation

- SCADA software solutions according to GAMP guideline

Materials

- EVA

- TPE

- TPU

Control

The touch screen control system is ergonomically designed and files all process as well as quality parameters.

Applications

- Medical yarn

- Drug-loaded strands

Customers

- Companies in the pharmaceutical sector

- Companies in the medical sector

- Universities and institutes