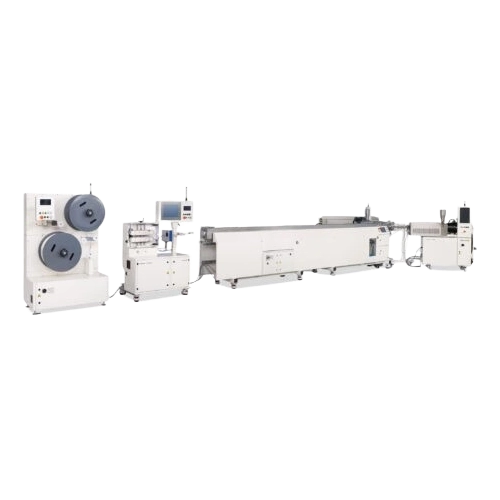

COLLIN tube lines are used for the production of multi-lumen resp. plastic tubes for medical applications, also multi-layer.

The spectrum of diameters ranges from thinner than a human hair (<100 µm) up to approx. 5 mm. By means of coextrusion, the properties of the tubes, with a design of up to 5-layers, are adapted to the requirements of the field of applications.

The inner geometry of COLLIN Medical Line tubes ranges from simple mono-lumen up to multi-lumen tubes, which contain up to seven channels, which are separated from each other. It is clear that all geometric parameters are extremely, narrowly tolerated. This geometric variety is multiplied by using different plastics.

Furthermore, polymer materials can be combined with metallic supporting bodies with different, geometric characteristics.

Advantages

- Up to 5 layers

- Up to 7 separate channels

- Manufactured according to FDA 21 CFR, ISPE, ISO 13485, Din EN 10204/3.1B, cGMP/GMP

- Construction & design correspond to the hygienic standards

- Easy cleaning

- Enormous variability in production

- Continuous production, compliance with all tolerance requirements

- Lines, which can produce around the clock

- Medically approved stainless steel for all parts having contact with the product

- Standard-compliant surfaces for easy cleaning and disinfection

- Standard-compliant validation, qualification and documentation

- SCADA software solutions according to GAMP Guideline

Materials

- PVC

- Polyethylene

- Crosslinked PE

- Silicone Rubber

- Thermoplastic Polyurethane

- Polyamide

- Fluoropolymer

Control

The touch screen control system is ergonomically designed and files all process as well as quality parameters.

Applications

- Minimally invasive surgeries

- Dialysis tubes

- Infusion tubes

- Catheter tubes

- Drainage tubes

- etc.

Customers

- Pharmaceutical companies

- Medical technology companies

- Universities and institutes